SMART PACKAGING

Reinvent Packaging with Purpose

The carbon footprint of a glass of wine may be less than that of a glass of milk, however we need to do everything we can as an industry to reduce it.

A big part of the carbon footprint is not from the farming or the wine making but from the manufacturing process of the glass bottles and packaging material.

Researchers estimate that approximately 38% of the carbon footprint for wines is associated with the packaging with the glass bottle 29% and the corrugate case box 6% being the largest contributors. (View study)

Key considerations for a more sustainable packaging system comprises of:

1) Lighter weight bottles – the weight of the empty glass bottle which directly impacts emissions in both manufacturing and transport.

2) Bottle Shape and Size – the shape and the size of the empty glass bottle which directly impacts emissions in cold warehousing, size of wholesale shipments and transport on pallets, containers and even shipping and gift boxes to retail locations and consumer residences.

3) Choice of material – percentage of recycled material used for glass bottle, packaging boxes, mailers, etc. – higher percentage of recycled glass uses less energy due to less heat and in many cases less rejection.

Lightweight bottles have been used for the transport and storage of wine, but for years many premium wines brands have been using heavy glass to promote the notion of quality measured by weight equating the heavy tactile feel of a bottle as a measure of quality for the consumers. This has many unintended consequences – it increases the carbon footprint from manufacturing to transport, it increases the cost of shipping and fuel surcharges. It also creates an unnecessarily heavy package for workers in warehouses and stores.

Round bottles are inherently inefficient with the amount of empty space around the neck and shoulder areas which needs to be protected and becomes negative space for shipping. Burgandy bottles are very inefficient for the larger bottom heavy bottles create a wide package during transport and warehousing. Taller slimmer bottles make a better use of space in a cubic box. Many wine experts recommend shipping wine in a lay down form to ensure contact between the cork and the wine. Round bottles are not the best in terms of laying down the bottles. Also the leading cause of breakage is round bottles smashing into each other during transit. The shape of the bottles supports vertical stacking not horizontal impact protection. As an industry we need to push forward with more effective and innovative ways of addressing this problem.

Unfortunately even though glass has infinite recycling properties we are falling short on recycling glass.

As of 2018, the glass industry reported recycling around 27 million metric tons worldwide, which represented some 21 percent of the total glass production in that year. Container glass accounted for the highest recycling rate among glass materials, with around 32 percent of waste recycled.

According to the EPA report published in 2019, the recycling rate in the United States is an appalling 39% vs 74% in Europe . (View report)

Packaging reform is being urged by many wine writers, critics and luminaries over the last year. In May 2023, Jancis Robinson OBE, MW delivered a captivating keynote address at the NAPA RISE conference in which she shared many actions across the globe by many vintners to reduce waste, manage scarce resources like water, and make better packaging decisions to lower carbon emissions.

Our founder Kia Behnia joined a set of thought leaders on a discussion panel on “the state of sustainability“ to discuss how best to take action and move towards a sustainable future for the industry.

SMART PACKAGING Philosophy: SYSTEM DESIGN

We designed the packaging for our wine in a systematic approach to create a new luxurious unboxing and user experience while cutting down on waste and improving the recycling of the used components.

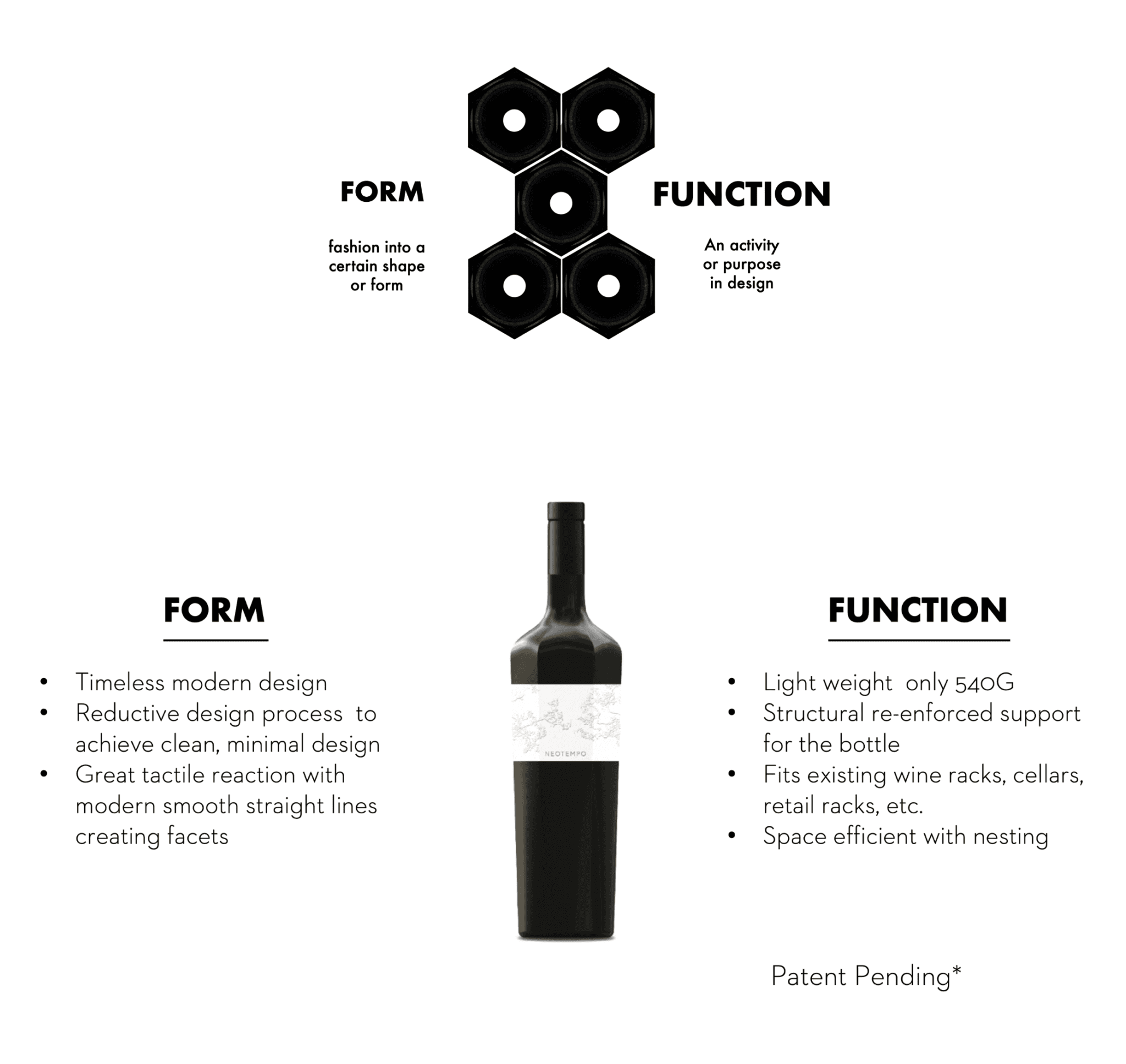

We fundamentally believe in the “less is more” philosophy and used reductive design to strip out non essential components and replace or remove any component made from plastic or derivatives like styrofoam. We also made sure that the components that made up our design balanced both form and function while minimizing the size, weight and material usage throughout the components of the package.

At the core of our packaging strategy is our unique proprietary hex bottle design that anchors all decisions on packaging, shipping, storage, and supply chain.

After we surveyed the market for lightweight bottles and testing them for packability, durability, aesthetics, and storage efficiency, we decided to design our own bottle to improve on the current bottles not just in reducing the weight but also addressing the problems with shape, size and material.

The bottle had to be lightweight but strong leveraging structural design. We needed to strengthen the bottle for shipping it on its side. Also in the future the bottle material can continue to evolve and get lighter and lighter glass. Geometry doesn’t change – manufacturing methods and materials do.

WHY A HEX BOTTLE?

Mathematically, the hexagon is a polygon with 6 sides – what makes this particular shape so interesting is that the hexagonal shape best fills a plane with equal size units and leaves no wasted space.

From a functional point of view a hex structure uses pull of surface tension in each direction which makes it the most mechanically stable. This explains how bee honeycombs are hexagonal – bees make their honey combs with circular units, but thanks to this surface tension, the end result when the wax hardens into place is hexagonal. Hexagonal packing like honeycomb, also minimises the perimeter for a given area because of its 120-degree angles.

Round cylindrical bottles are the de-facto standard in the wine industry but there are no standard dimensions or standard weight specifications. Round significant disadvantages over other shapes. One of the big disadvantages is there is a big “air gaps” between bottles in conventional packaging design for round bottles.

We designed a hybrid bottle that has polygon shoulders and round on the bottom.

This shape create two sides to every bottle – a “skinny” side for packing and transport and a “broad” side for displaying the bottle – round and square bottles don’t have this capability. This feature has been proven in our case to put 25% more bottles on the same pallet, reducing the number of containers on a boar, trucks needing to ship.

Our bottle design minimizes wasted space in the shoulder and neck area and also allows the bottles to nest together to form a honeycomb. It also provides strength and resilience when the bottle is placed flat. The hex shape also provide structural strength to the bottle for compression particularly when it is laid down – like good wine should to maintain a wet cork.

Our bottle is round on the bottom and also in the neck area allowing it to leverage existing bottling lines and capsules and corks. Don’t worry we have tested our hex bottles on plenty of rack systems and are confident that it will fit well in your cellar, wine tote and wine refrigerator.

From a aesthetic standpoint a hybrid shape creates facets resembling diamonds and provides a different way for light reflects off of the glass.

Bottom line: This patent pending design allows us to ship lighter bottles to reduce both the carbon footprint and shipping costs for us and our customers. Our final bottle design is 20-50% lighter than other luxury wine bottles and up to 20% slimmer in the shoulder area. This enables a substantial reduction in the carbon footprint of the wine and more efficiency while in manufacturing, transport and storage. But our bottle is not just another lightweight bottle. It’s designed for efficient transportation.

INTERACTIVE 3D Model of our Hex Bottle – Swipe or click to view from all angles

"WILD GLASS" Material Selection

Our standard 750 ml glass bottles are made with 100% post consumer recycled PCR called “wild glass” by which is an industry first innovation by Estal. We worked closely with Estal to have them produce our patent pending design in wild glass. We will also use their designs on our magnums and other formats. (Read more about wild glass from Estal’s)

Estal is an industry leader in innovation in glass manufacturing and they have a wide range of bottle shapes in wild glass which would be great options for other wineries who don’t want to invest in custom designs but would like to use 100% PCR glass for manufacturing.

DESIGN PROCESS DETAILS: Balancing Form and Function

Throughout our lives we always were intrigued by designs that balance form and function. The balance seems to use design as a way to solve problems and give purpose to the design. This concept became paramount as we considered the design for our wine bottle. We started with three set of problems and design objectives:

Firstly, light weight bottles seem weaker and less striking to the eye and less sturdy to the touch. From a form perspective the bottle had to visually and from a tactile perspective capture luxury and elegance – and feel good to the eye and to the touch. Functionally and ergonomically it had to feel steady while pouring and also look striking when being presented.

Secondly, round bottles are not stable when on their side. From a functional perspective we wanted to optimize for laying the bottle on its side to wet the cork throughout the process of shipping and storing.

Thirdly, round bottle waste a lot of space around the neck area and need a lot of packaging to keep them from hitting one another. From functional perspective it needed to be designed for packing efficiency and compatibility in our consumers cellars, and other existing wine storage. The design also needs to consider the form again to innovate on new configurations and new visually appealing designs for packages and displaying the final product as a collection or in a single bottle package.

We prototyped the bottle using a 3D printer and iterated through 42 designs until we landed on a design that best captured elegance, modernity and the lightest weight that the factory allowed us to manufacture. We worked with sommeliers, wine critics, and many consumers to solicit feedback and get their input.

DESIGN PROCESS